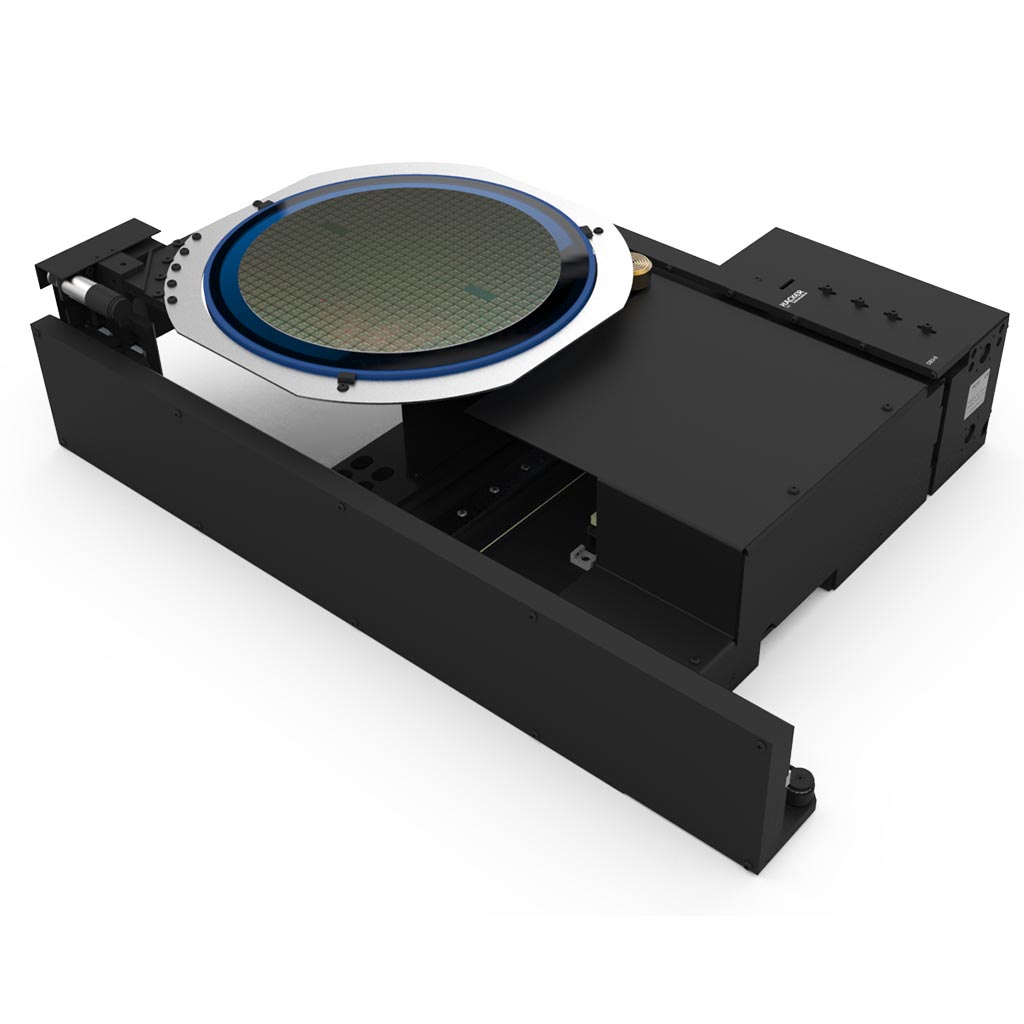

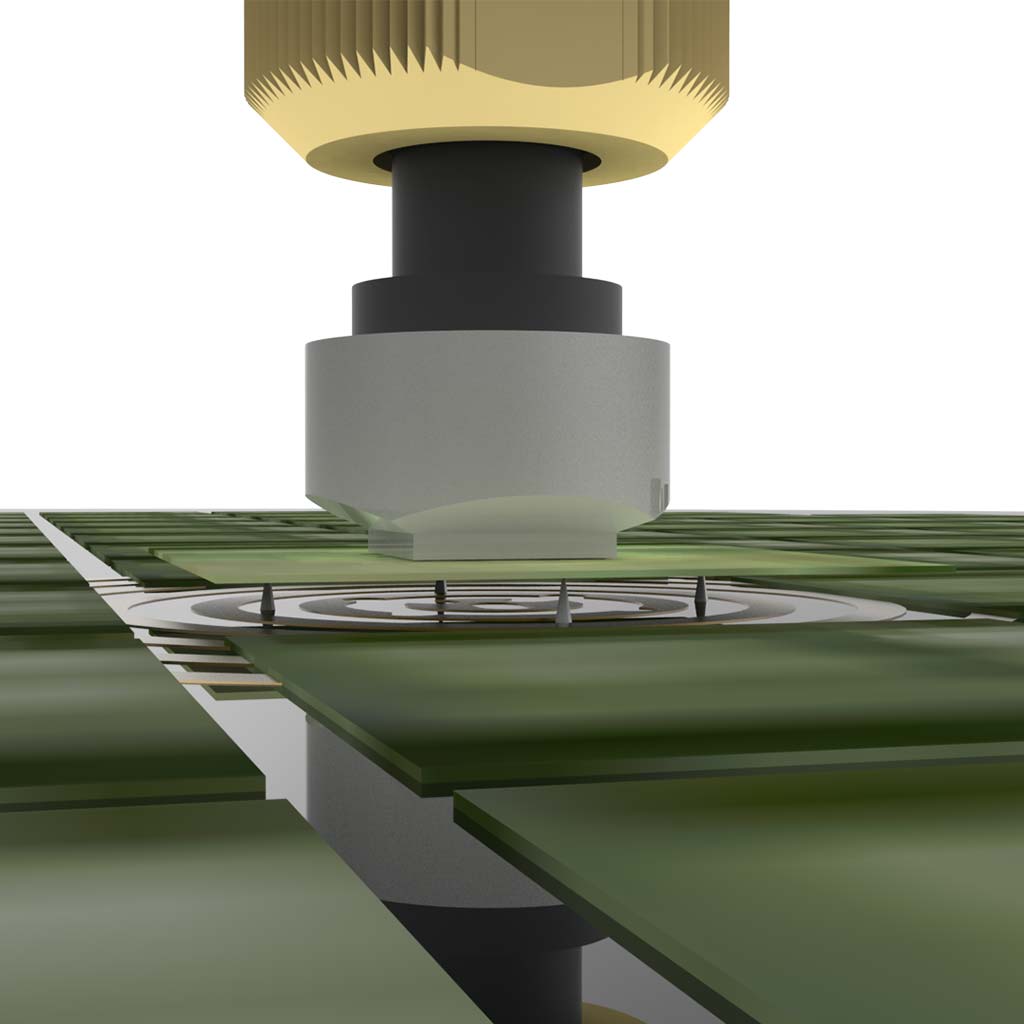

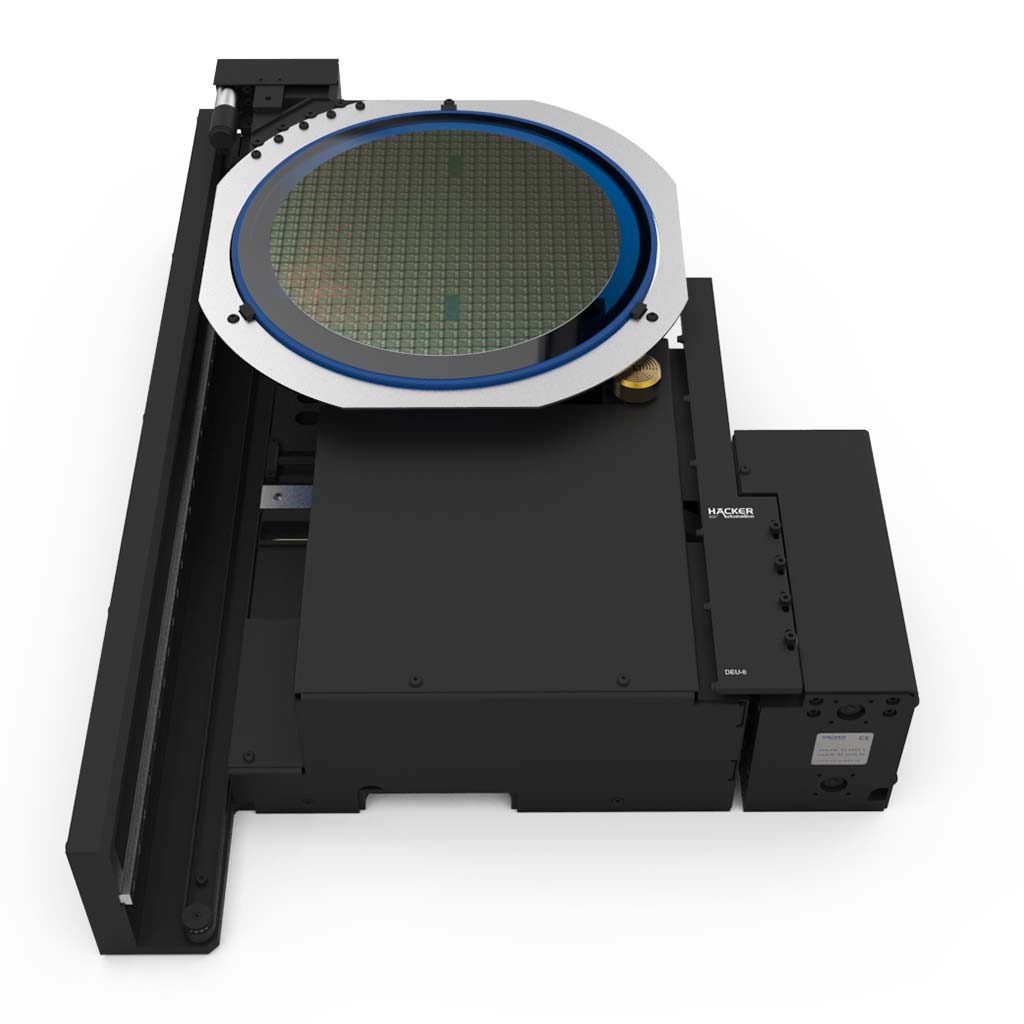

The Die Eject Unit has a needle system that ejects the components fixed to the film for transfering them to the assembly system. By replacing the manually exchangeable needle system and the wafer frame adapter, a wide range of components are processed from wafers of up to 8 inches in size. The speed of the ejecting needles is synchronized to the assembly system and is component-specific selectable.

The adapted wafer automatically loaded and unloaded by the wafer system.

The Eject Unit is available with a needle holder with lid and needle (needle-vacuum system) and a wafer adapter (selectable). By using special optional adaptations also Waffle-Packs can be processed on the module.

For loading of the wafers you can choose between a single wafer loader or an automatic wafer changer for up to 7 wafers.