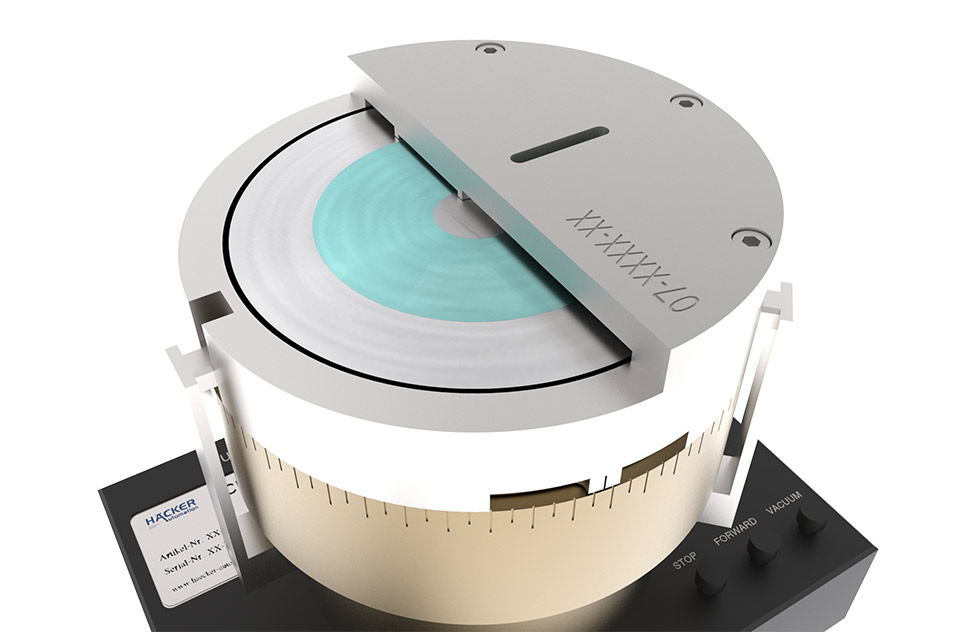

irect dispensing is a dispensing method for applying liquid and jellylike substances directly to the workpiece’s underside. The principle is similar to that of a stamping or pin transfer process. The difference is that here the workpiece forms its own reference for the substance application. This means that the workpiece itself is used as a stamping tool for the substance transfer. The entire workpiece or an individual area, such as connection pads, is used as a reference surface for wetting. The substance is provided on a foil that is formed by means of a vacuum structure. Respective process requirements are realized by arranging and exchanging of several structures as well as providing different substance thicknesses.

General workflow of the direct dispensing process:

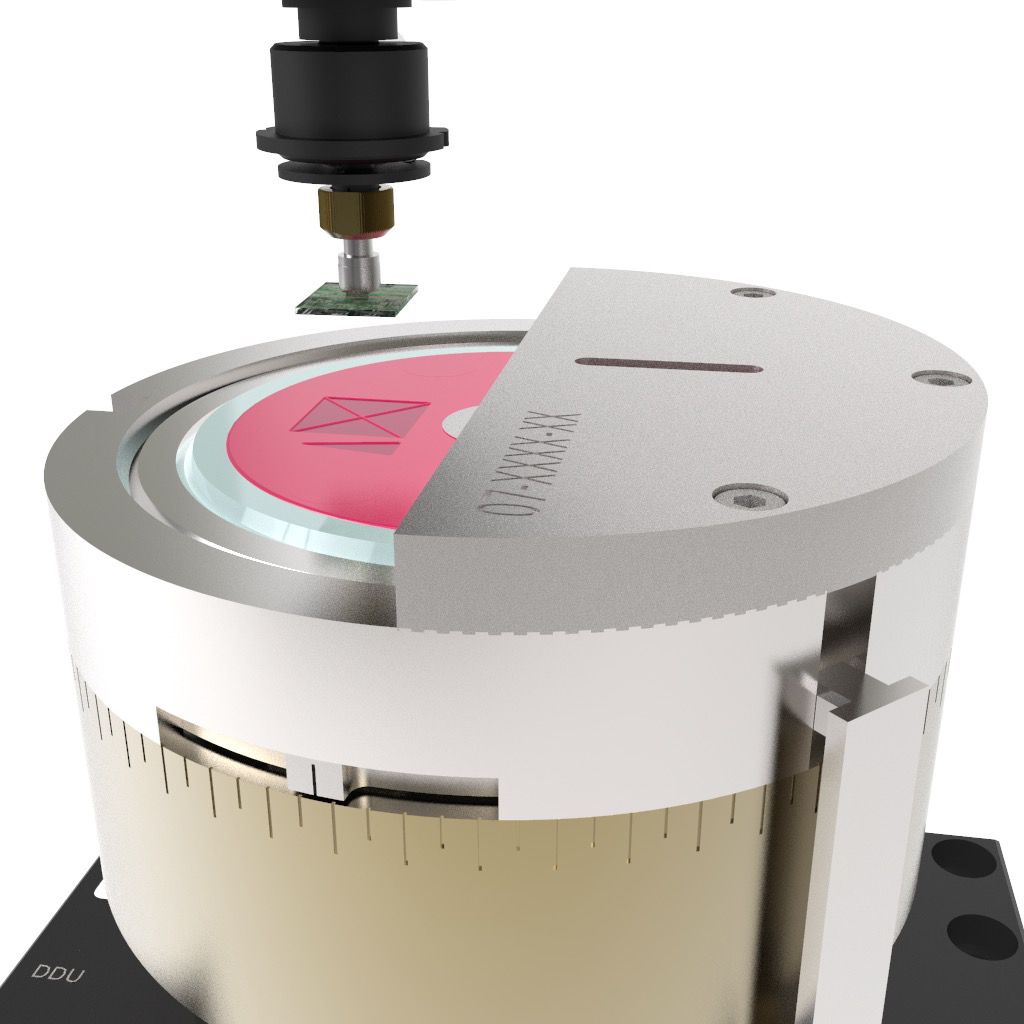

- The workpiece is immersed in the substance. There is wetting on the underside and, under certain circumstances, also slightly on the lower lateral surfaces of the workpiece.

- The foil with the substance is structured according to the process requirements before or after the workpiece is immersed.

- The workpiece is lifted out of the substance again.

- If the workpiece is lifted out far enough, the substance will tear off, with parts of the substance remaining on the workpiece.

- The workpiece with the substance is now ready for further processing, e.g. for assembly on a carrier substrate.

Direct dispensing is usually used in the following process steps:

- Partial or full surface wetting of the workpieces‘ underside

- The substance is applied directly to the workpiece to be assembled

- Chip gluing with chip-on-board

- Time-critical processes between substance application and workpiece placing

- special forms of the dispensing material or the connection point

References

[1] Offenlegungsschrift DE000010145396A1

[2] Patent DE00001145396B4

[3] International patent application WO002002022278A2

[4] International patent application WO002002022278A3