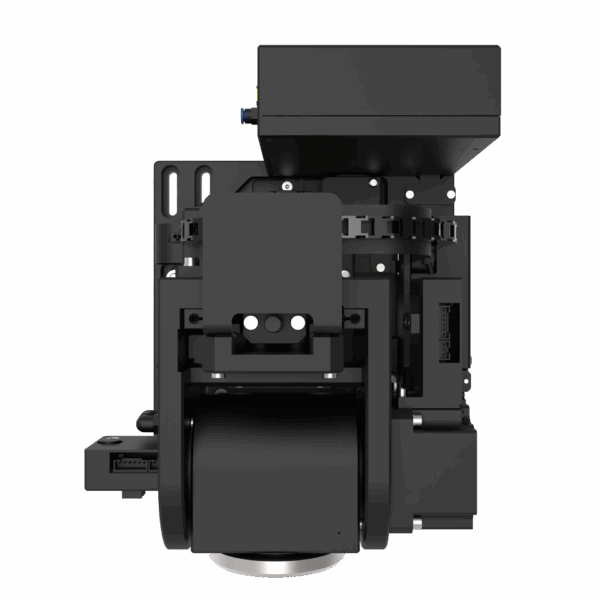

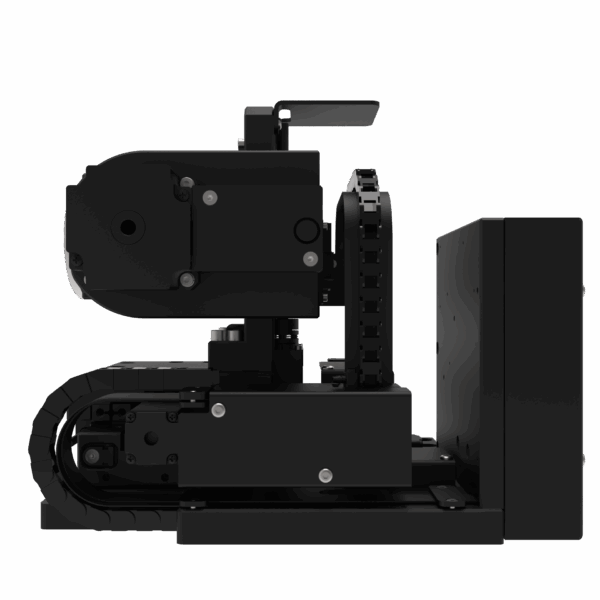

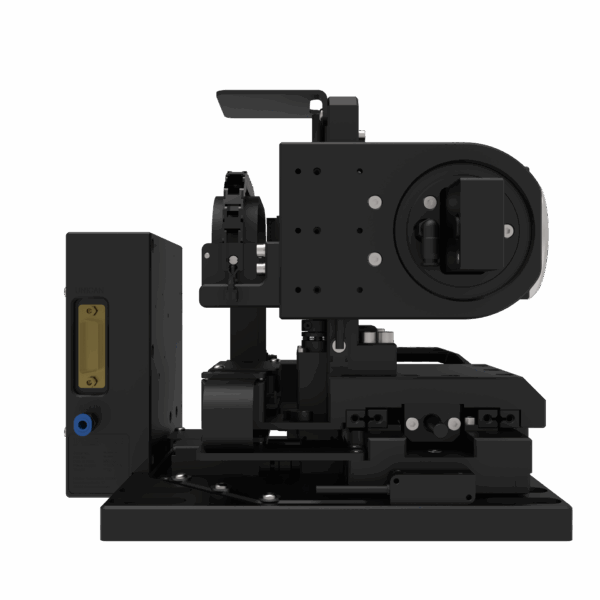

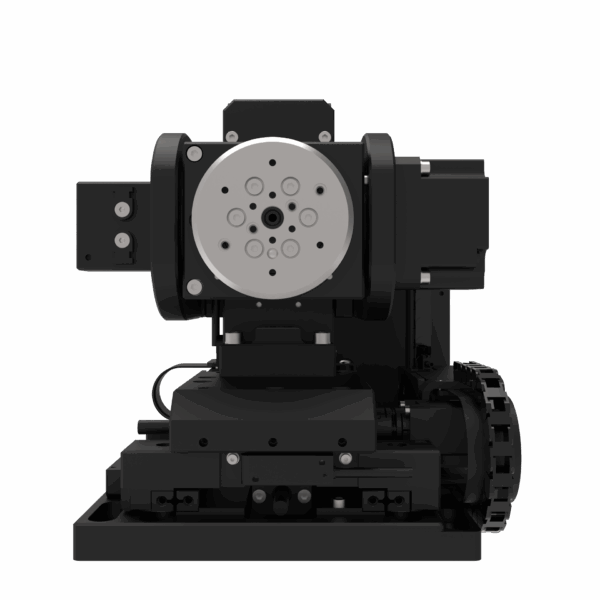

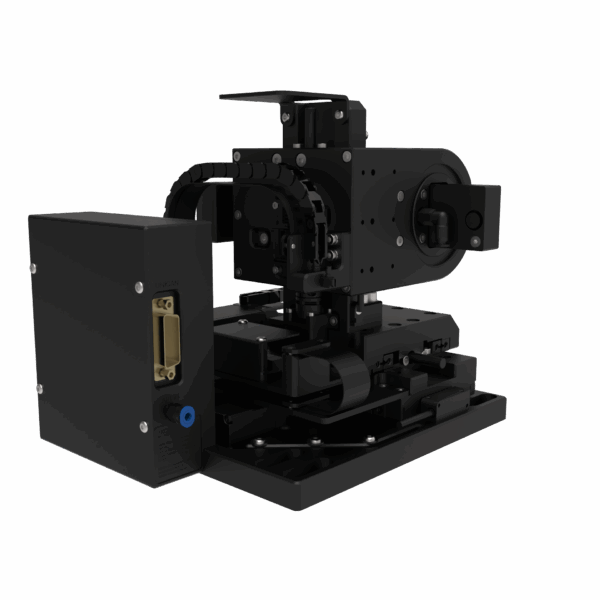

5-Axis-Manipulator

49.500,00 € excl. VAT

Description

The 5-axis manipulator offers a precise and versatile solution for picking up components using vacuum and then manipulating them in the XYZ axes and around rotational and tilting axes. Developed for demanding manufacturing and assembly processes, the system impresses with its accuracy, repeatability, and robust design.

Detailed features:

- Vacuum pickup of components: Reliable suction gripping technology with adjustable vacuum pressure, interchangeable tools, and secure component fixation for a wide variety of contours and materials.

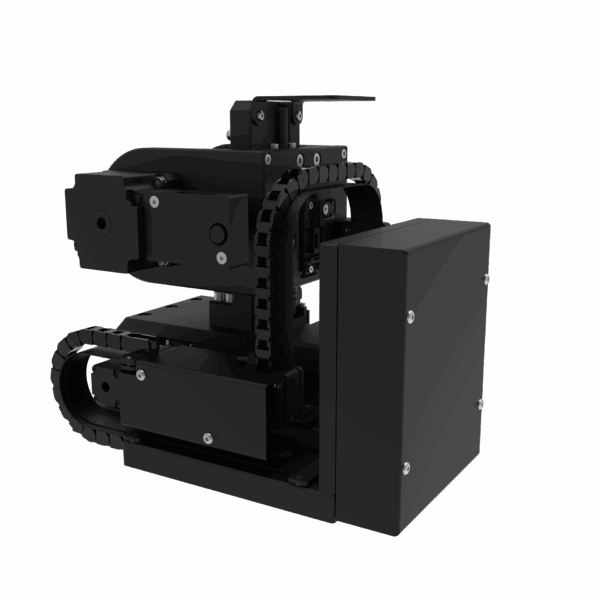

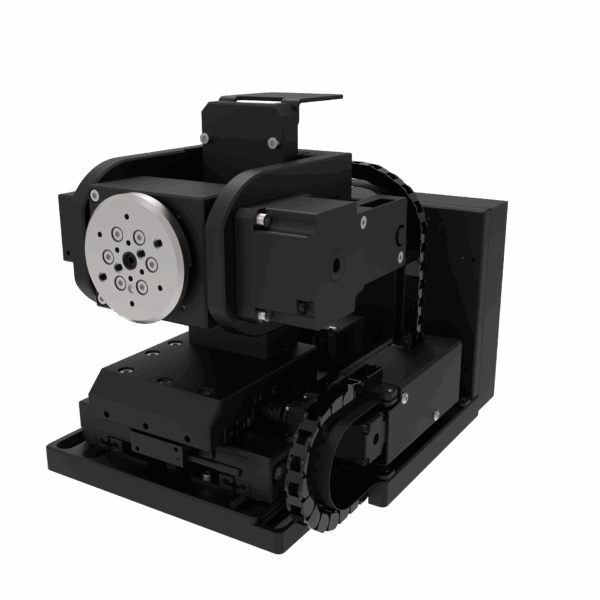

- 5-axis movement: Combined control of X, Y, Z for positional placement, plus rotation axis (A) and tilt axis (C), enables complex motion sequences and flexible gripping and assembly processes.

- Manipulation in XYz (50 mm): Fine-tuned movements in the working area with a resolution/travel distance of up to 50 mm in Z and precise positioning in X and Y for exact component guidance.

- Rotation and tilt axis: Rotation/tilt movements allow the component to be aligned at almost any angle, ideal for assembly steps, quality checks, or adjustments.

- Rotation and tilt axis: Rotation/tilt movements allow the component to be aligned at almost any angle, ideal for assembly steps, quality checks, or adjustments.

- High repeatability: Calibrated sensors, stable structures, and advanced control ensure consistent results across numerous series runs.

Integrated safety: Vacuum and motion monitoring, emergency stop functions, and safe gripping force control protect operators and components. - Open interfaces: Compatible with common PLC/robotics systems, easy integration into existing automation environments.

- Robustness and maintenance: Robust material selection, low-wear components, and accessible maintenance points minimize downtime

Application scenarios:

- Precision assembly of small to medium-sized components

- Series production with repeatable gripping and assembly processes

- Quality inspection and measurement while maintaining precise orientation of the component

Advantages:

- Higher productivity through fast setup times and flexible process adaptation

- Improved component quality through precise axis guidance and repeatable positioning

- Scalability and easy integration into existing assembly systems

Additional information

| Dimensions in mm (W x D x H) | 365 x 80 x 112 |

|---|---|

| Weight in kg | 5,0 |

| Movement range in Z in mm | 50 |

| Movement range rotation axis in degree | 0 … 360 |

| Movement range swivel axis in degree | ± 90 |

| Max. moving load in kg | 9 |

| Voltage in V | 24 |

| Max. current in A | 3 |

| Communication interface | UNICAN |

SKU:

S3-0104

Categories: Feeding equipment, Modules, smart modules