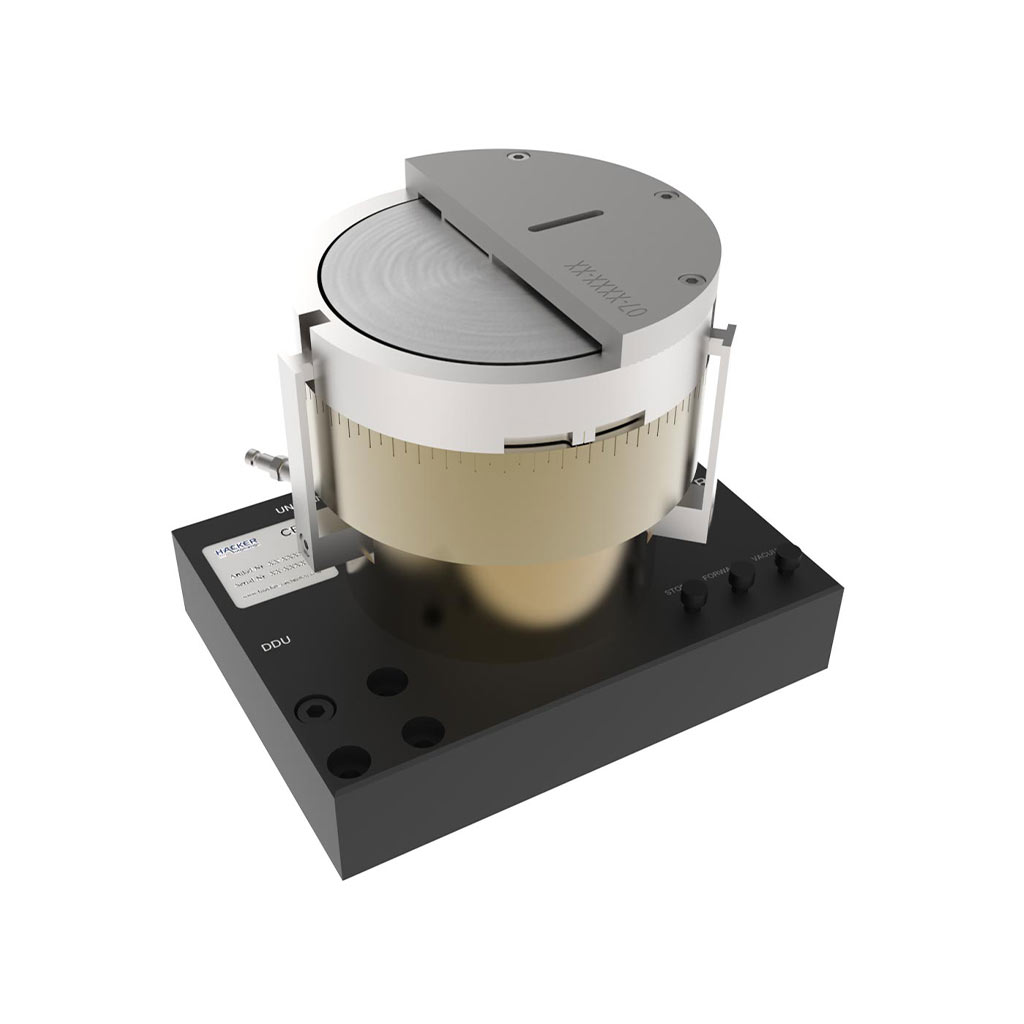

Direct Dispensing Unit

16.200,00 € excl. VAT

The Direct Dispensing Unit provides dispensing materials with a defined thickness and distribution. It is possible to choose between the technologies “Direct Dispensing” and “Pin Transfer”.

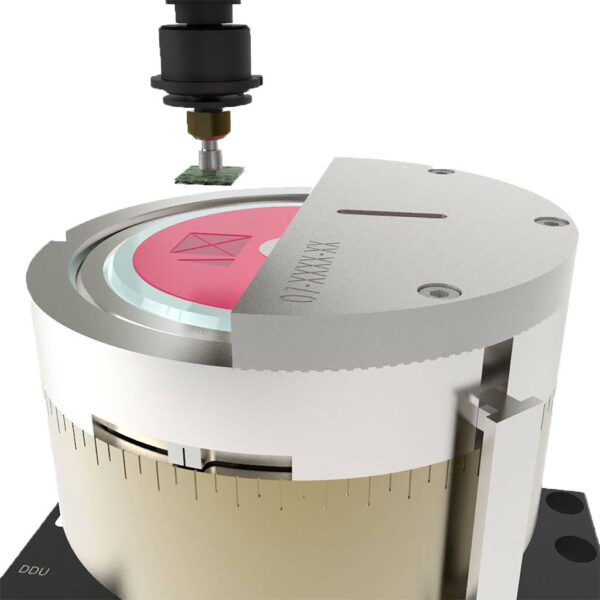

The Unit is designed to provide a homogeneous media layer at the subside of the microelectronic components to be assembled in the process. The component is also the stamping tool for direct dispensing. Thus, the adhesive is always applied at the component subside, making it possible to realise even the smallest placements.

Within the pin transfer process, process-specific stamping tools transfer the desired pattern. Similar to drop-shaped needle or jet dispensing, the Direct Dispensing Unit applies a homogeneous and reproducible adhesive layer. This prevents certain areas of components or substrates from being inadvertently wetted with adhesives.

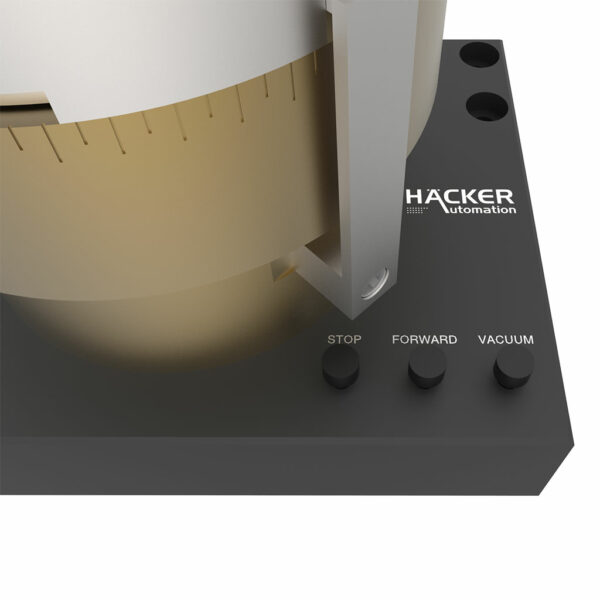

The structure of the vacuum circular blank and the shape of the dispensing track are defined by the process-specific squeegee plate.

Thanks to the modular design of the Direct Dispensing Unit, the module can be disassembled by the user to the relevant individual parts, which simplifies maintenance and cleaning.

| Dimensions in mm (W x D x H) |

145 x 108 x 127 |

|---|---|

| Weight in kg |

2.4 |

| Dispensing track height |

Scales height adjustment of the squeegee plate |

| Adjustment range in mm |

0 … 4 |

| Adjustment accuracy in µm |

5 |

| Voltage in V |

24 |

| Max. current in A |

0.5 |

| Communication interface |

UNICAN |

| Operating temperature in °C |

20 … 35 |