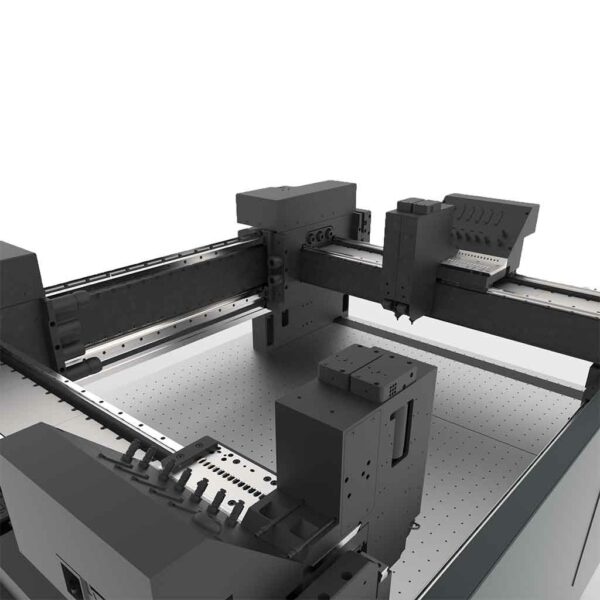

X3 | Large-scale production

295.000,00 € – 374.000,00 € excl. VAT

The OurPlant X3 is a mini-factory for micro assembly that combines individual and complex processes with high speed. Like all micro assembly machines of OurPlant, the machine is based on a modular design. Thanks to the high variability of processing heads and base plate modules, the OurPlant X3 enables the highest level of process diversity and flexibility. Micro assembly and micro dispensing tasks can be realised in combination.

The machine has an option area of the base plate in the front. In this area the base plate is completed either by a fixed perforated grid plate or a trolley system.

It is possible to equip the OurPlant X3 with a second Y-axis. The OurPlant X3 blue² has two independently working Y-axes. That allows the use of twice as many processing heads. The advantage: complex processes can be realised in parallel and thus the cycle time is reduced.

Technical information:

- Machine frame and housing with integrated UV protective glass, optionally with laser protective glass

- Processing heads with integrated Z-axis

- Operating panel

- Software and control with integrated industrial PC

- one interface per portal with 10 electrical connections (5x CAN, 5x Ethernet) for taking up processing modules up to a total width of 250 mm

Advantages:

- Ideal for medium to large batch sizes

- low set-up effort thanks to real “Plug & Play” capability

- easy integration into a production line by using a transport system

- software-based system control via touchscreen

Variants of the OurPlant X3:

OurPlant X3 blue

2-axis gantry system (X, Y) of aluminium

OurPlant X3 blue²

double axis portal system of aluminium

Extension:

All variants of the OurPlant X3 can be ordered with an additional protective housing, which serves the laser protection (wavelength 940 nm – 1065 nm).

| No. of axes | one Y axis, two Y axes |

|---|---|

| Safety enclosure | UV and laser protective glass (wave length 940 – 1,065 nm), UV protective glass |

| Dimensions in mm (W x D x H) | 1.900 x 1.500 x 2.059 |

| Installation surface / centre distance of the machine feet in mm (W x D) | 1.640 x 895 |

| Min. distance to surrounding objects in mm | 600 |

| Weight in kg | ca. 3.600 |

| Max. functional area in mm (X,Y) | mit einer Y-Achse: 1.200 x 700, mit zwei Y-Achsen: 700 x 700 |

| Repeatability in mm | ± 0,001 |

| Max. speed x-axis in mm/s | 2.100 |

| Max. speed y-axis in mm/s | 2.100 |

| Max. acceleration x-axis in mm/s² | 10.000 |

| Max. acceleration y-axis in mm/s² | 10.000 |

| Power Supply | 400 VAC, 3L + N + PE, 50 … 60 Hz, 16 A |

| Average energy requirement in kWh | 2 |

| Compressed air requirements | ≥ 5,5 bar (optimal > 6 bar), 180 l/min, gereinigt, trocken, ölfrei |

| Max. realitive humidity in % | 60 |

| Certification | CE konform, ESD Schutz |