Smart Tools

2.450,00 € – 25.000,00 € excl. VAT

A completely new way of building devices.

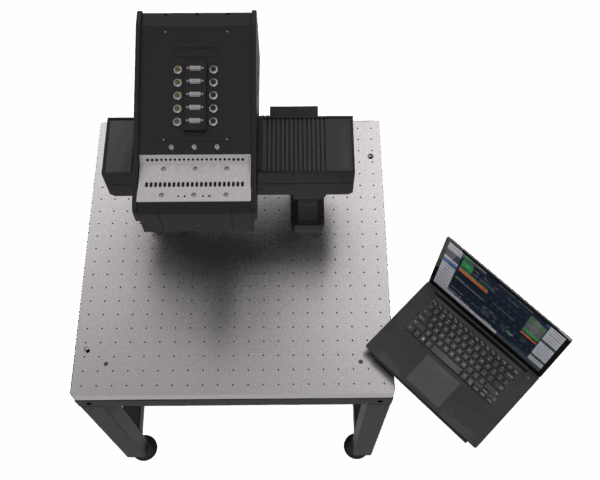

With Smart Tools and the extensive portfolio of modules, you can easily put together your own individual process solution. These smart tools offer a wide range of technical solutions for dispensing, placing, inspecting and measuring. Thanks to the wide range of components and functions, you can efficiently design, adapt and optimize processes according to your requirements. The result is a tailor-made, intelligent tool that helps you to successfully implement your projects

Four core elements form the basic device for your individual Smart Tools.

S4-0001 Core-Unit-XT: As the central component of the OurPlant Smart Tools, this control unit enables intuitive operation and comprehensive control of the entire setup. It ensures that all processes run smoothly and the desired results are achieved.

Dimensions (W x D x H) 340 x 150 x 180 mm

Weight approx. 10 kg

S4-0002 Portal-32-XT: This unit consists of a high-precision motion system with a travel range of 300 mm x 200 mm. The portal can accommodate up to three machining heads. Combined with fixtures that can be freely positioned on the frame, this results in high application flexibility. Various machining processes can be implemented efficiently.

Dimensions (W x D x H) 600 x 470 x 536.5 mm

Weight approx. 60 kg

Technical Data Travel Range:

Axes: 200 mm

300 mm

S4-0003 Machine-Frame-XT: This stable and vibration-damped frame forms the basis for all other components. It ensures that the process units and fixtures can be positioned safely and precisely.

S4-0004 Notebook incl. Sideboard: The rotating sideboard can be attached to either side of the frame, ensuring optimal ergonomics. The Dell notebook has a 15-inch screen and comes with Windows.

S4-0005 OurPlant OS Packages: OurPlant OS ensures the reliability of your developed processes. Using the software interface, you configure your selected modules and combine various process steps (placement, dispensing, etc.) to create your individual production recipe.

- Production operating system

- Recipe programming

- Modular process and hardware control

- Open Source

| Weight in kg |

375 (without modules incl. notebook) |

|---|---|

| Dimensions in mm (W x D x H) |

1160x800x1370 |

| Max. functional area in mm (X,Y) | |

| Repeatability in mm |

± 0,001 |

| El. Anschluss |

230V, 24V, 48V, Ethernet, Unican |

| Max. speed x-axis in mm/s |

250 |

| Max. speed y-axis in mm/s |

250 |

| Compressed air requirements |

≥ 5 bar (optimal > 6 bar), 100 l/min, gereinigt, trocken, ölfrei |

| Operating temperature in °C |

20 … 35 |

| Max. realitive humidity in % |

60 |